In a world where engineering marvels and cutting-edge technologies drive progress, one often overlooked but crucial aspect remains at the heart of it all: Friction and Wear Testing. It’s the unsung hero that ensures your car’s brakes don’t fail when you need them most, your airplane’s landing gear can withstand countless landings, and your favorite kitchen gadgets remain smooth and efficient.

Without rigorous testing, the machinery we rely on daily would succumb to the forces of friction and wear, leading to costly breakdowns and safety hazards. In this blog post, we’ll delve into the significance of Friction and Wear Testing Services, uncovering the vital role they play in the durability and safety of the products we depend on. Let’s get started.

Quality Control

Friction and wear testing services play a pivotal role in quality control for various industries. By subjecting materials and products to rigorous friction testing, manufacturers can assess their resistance, wear, and abrasion, ensuring that they meet predefined standards and specifications. These tests help identify potential defects, weaknesses, or design flaws early in the manufacturing process, allowing for necessary adjustments and improvements.

As a result, businesses can consistently deliver high-quality products to their customers, reduce the risk of premature failures, and uphold their reputation for reliability and performance. Quality control through friction and wear testing is essential for meeting customer expectations and industry regulations.

Material Selection

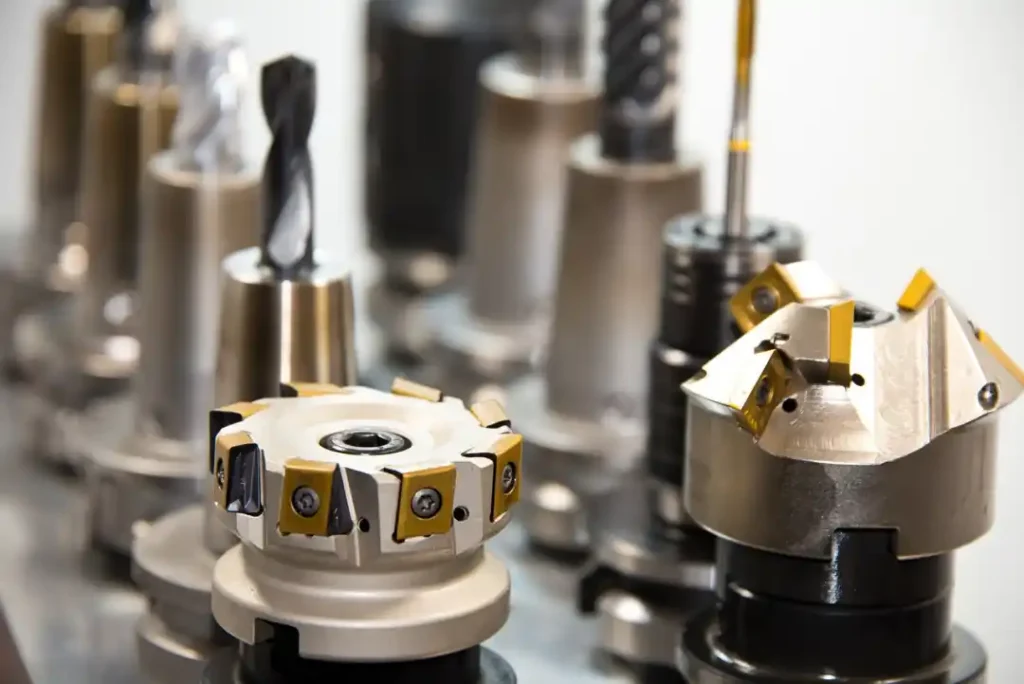

Friction and wear testing services are invaluable in the realm of material selection. Engineers and designers rely on these tests to make informed decisions when choosing materials for specific applications. By subjecting potential materials to controlled friction and wear conditions, they can assess how well these materials will perform in real-world scenarios.

This information guides the selection of materials that are best suited for the intended use, whether it’s in automotive components, manufacturing machinery, or medical devices. Material selection based on friction and wear data not only enhances product durability and performance but also reduces the likelihood of costly failures, ultimately contributing to more reliable and efficient solutions.

Performance Optimization

Friction and wear testing services are instrumental in the pursuit of performance optimization. Companies utilize these tests to fine-tune their products, materials, and processes. By analyzing the data generated from these tests, they can implement improvements in surface treatments, lubrication strategies, and design features. This data-driven approach allows for the enhancement of product efficiency, longevity, and reliability, often reducing maintenance requirements and associated costs.

In industries such as aerospace, automotive manufacturing, and industrial machinery, where precision and reliability are paramount, performance optimization through friction and wear testing is a crucial step in staying competitive and meeting the ever-evolving demands of customers and regulatory standards.

Regulatory Compliance

Friction and wear testing services are pivotal for ensuring regulatory compliance in industries with stringent quality and safety standards. Many sectors, including aerospace, healthcare, and automotive manufacturing, are bound by specific regulations governing product performance and durability. These tests provide the essential data required to demonstrate that products meet or exceed these industry-specific norms and regulations.

By consistently conducting friction and wear tests, companies can verify their products’ reliability, reduce the risk of non-compliance, and uphold their commitment to safety and quality. This not only fosters consumer trust but also safeguards against potential legal and financial ramifications associated with non-compliance, making friction and wear testing a critical component of business operations.

Friction and wear testing services offer multifaceted benefits to various industries. From quality control and material selection to performance optimization and regulatory compliance, these tests empower manufacturers to enhance product reliability, efficiency, and safety. By providing invaluable insights into a material’s ability to withstand friction and wear, these services contribute to the development of high-quality, durable products, bolstering customer satisfaction and ensuring adherence to rigorous industry standards. Embracing friction and wear testing is not merely a choice but a necessity for companies committed to delivering excellence and remaining compliant in today’s competitive markets.